The advantages of a TAKEMOTO partnership

Together Lab

Product Flow

We will bring your ideal container to life. We manufacture custom containers that are unique to the customers’ needs. We can meet a wide range of requests such as shape, color, size, graphics as well as sustainable materials, functionality, and quick supply. Whatever your needs, please feel free to contact us.

We will discuss the shape, design, contents, material, quantity, supply date, quality, cost, etc. of the desired container according to the customer’s product concept. Depending on your budget, we can also offer custom containers in combination with some of our ready-made products and combinations with our vast range of accessories.

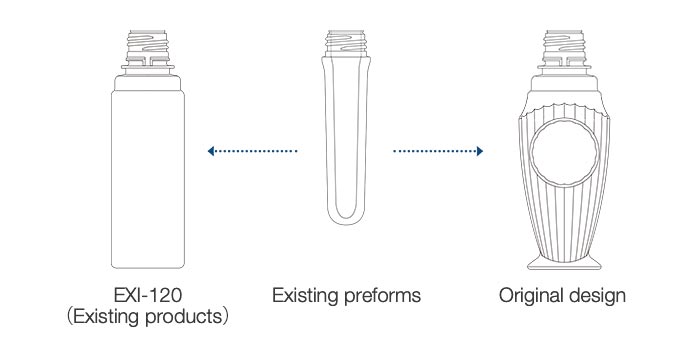

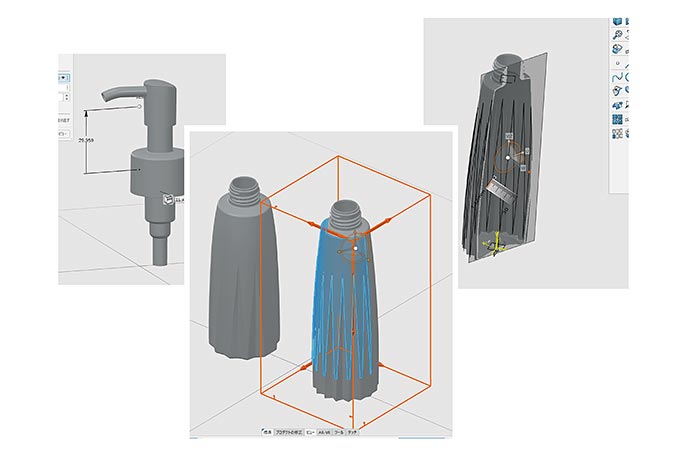

We will give shape to your ideas and images. We will create product drawings and 3D data from sketches of the customer’s design. It is also possible to prepare drawings from the data provided by the customer. We use digital tools to produce a 3D image to simulate the form of the container, the decoration method, and the combination with accessories. 3D models and design drawings are provided to confirm the final result. For coloring, we can introduce options from a wide range of color samples. For decoration, we will propose various decoration methods to achieve your graphic design using various secondary processing methods. After confirming the details, we will present an estimate of the unit price of the product.

We will reproduce the design according to the customer’s requests. If the container will be colored, please present a color sample. We will quickly prepare color plates and cups according to your desired schedule. If printing is required, please submit the design data.

The final product drawing and model will be confirmed. After confirming the total product balance including the product form and accessory, the sense of size, and the suitability of secondary processing via 3D simulation, the final detailed design drawing of the product will be approved.

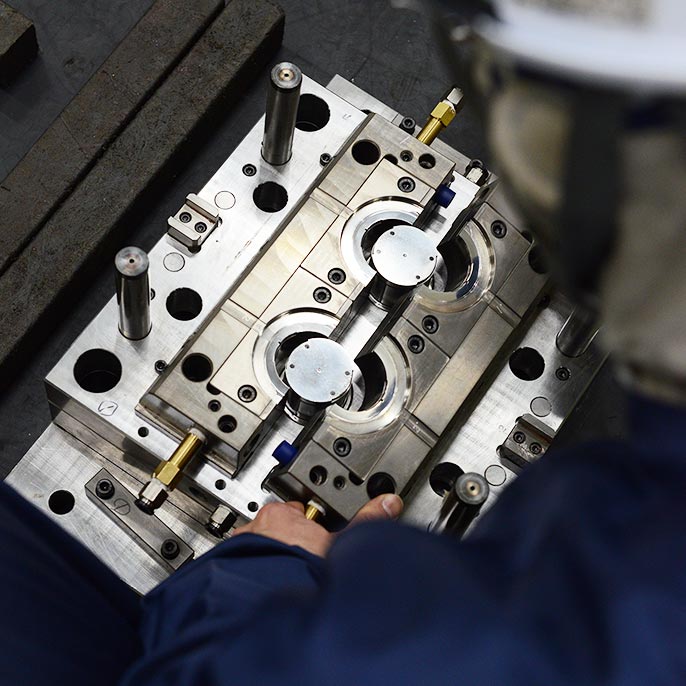

Together with the approval of the product design drawing, the mold is ordered by the customer. Molding tools will be produced based on the approved drawing. The production period varies depending on the molding method of the container, size, and shape.

With trial production, we will produce an actual bottle according to the design image. This is the final confirmation before the final production.

With the pre-production sample, the customer will verify and evaluate the usability of the trial product. After this final confirmation, approval samples are submitted by the customer for Quality Assurance purposes.

The details of the quotation are confirmed and a purchase order is placed.

Final production is commenced.

We will supply the products after they have cleared quality inspection on the appropriate date.